Compliance with EPA Tier 4, or any other Federal/State regulatory requirements, is not optional. All manufacturers must comply if they wish to continue to sell diesel-powered products in this kilowatt or horsepower/performance range.

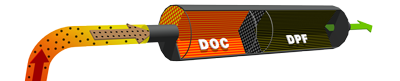

While Tier 4 may seem “new” to many in our business, The Toro Company has been working with our engine suppliers over the past decade to successfully comply with each Tier of the emission regulations. Since the compliant engines to meet progressively higher emission standards were more easily interchangeable in the past, much of the burden to implement the required changes fell on engine manufacturers. Going forward, however, incorporating new Tier 4-compliant diesel engines into turf equipment requires significant equipment redesign because the level of emission reductions mandated in this stage will require more sophisticated fuel injection/combustion systems and exhaust after treatment systems.

Each of the new diesel engine/exhaust systems:

Significant redesigns were required to integrate the above Tier 4-compliant diesel engine changes with existing equipment/models. Examples include: retooled engine compartment housings, modifications to chassis frames, and re-engineered cooling systems to manage higher temperature exhaust, to name a few. In many cases over a third of the parts for a given model had to be reworked, replaced or otherwise re-engineered! Because of this, existing models were simply not “retrofit” capable. Toro, alone, produces over twenty diesel-powered models in the 18.6 to 55.2 kilowatt (25 to 74 horsepower) range that had to be addressed.

The obvious message, which no manufacturer wants to convey, is that the design, manufacturing and component costs – to deliver Tier 4-compliant diesel-powered products has increased significantly on machines manufactured in 2013. Cost reductions, while always a high priority in product redesigns, are not sufficient to offset cost increases.